Swarm Chats: Rob Meyerson, Former President of Blue Origin

December 16, 2020

The space sector has long benefited from cross-industry innovation, and today’s intersections – from cybersecurity to supply chain management – are as critical as ever.

Rob Meyerson has a frontrow seat view to what the latest technologies can enable in the aerospace industry. As an operating partner at C5 Capital, Rob works with cutting edge companies at the intersection of space, cloud computing, AI, and cybersecurity. Rob’s impressive career also includes 15 years at Blue Origin, leading Jeff Bezos’s space company from 10 to 1500 people and, more recently, building Blue’s Advanced Development Programs business unit from scratch.

We sat down virtually with Rob to discuss the importance of a smooth supply chain, the future of 3D printing in space, and what companies like Swarm will mean to the future of the IoT market.

Sara Spangelo: What are you most excited about in the space industry right now?

Rob Meyerson: I joined C5 Capital recently as an operating partner, and the reason I joined is to have the opportunity to invest in the digital transformation happening in the space industry. There are many opportunities for companies operating at the intersection of space, cybersecurity, and cloud computing. We are becoming more and more reliant on space for communications; positioning, navigation and timing; weather monitoring; earth observation and other services, like IoT. These space systems now serve as utilities, a part of our critical infrastructure, that we rely on for everything from predicting weather events, to tracking wildfires, to pumping gasoline.

I’m also interested in companies operating in the lower tiers of the supply chain. There’s a lot of support that’s needed to build businesses like Swarm. There hasn’t been a lot of innovation in the component suppliers and machine shops. The most innovative companies get swallowed up by the big industry primes almost too quickly. We all suffer from the challenges of getting parts and components delivered on time to meet our needs, and there are a lot of improvements that can be made in the supply chain through digital transformation and from improving operations. There are opportunities for the traditional tech industry and the aerospace supply chain to partner up and learn from each other.

We all suffer from the challenges of getting parts and components delivered on time to meet our needs… There are opportunities for the traditional tech industry and the aerospace supply chain to partner up and learn from each other.

SS: I’m reflecting on what has potentially limited Swarm in our ability to deliver satellites – which luckily has never actually stopped us – but delivery of solar panels, for example, can have six- to eight-week lead times. Recently sending out our Swarm Tiles, it’s been radials or brackets or battery holders – small stuff that means we can’t send products out because we’re waiting on deliveries.

RM: I’ve seen 22-week lead times. Imagine you take delivery of a bent tube and your design was wrong or you missed something and you have to start all over again. It’s that last mile of the integration cycle where you’ve got your vehicle structure and all of your components installed and now you’ve got to hook things up with wire and tubes… it’s much harder than it needs to be. There’s a real opportunity for technology to bring those businesses forward.

Then there’s also the digital data set coming from customers. In many cases it’s a 2D paper drawing. Do you need to create that, or can you transfer that definition digitally and shorten the cycle, and validate it before you build in a way that ensures you deliver the right part the first time?

SS: How do you feel about 3D printing, like what Relativity is doing, as a way to overcome some of these challenges?

RM: I’m really excited about it, especially Stargate building large, monolithic structures. Building a rocket propellant tank, for example, requires very specialized aerospace processes. What Relativity is doing with printing all-in-one is going to have huge downstream benefits. Not just for rockets but for other businesses as well.

SS: What do you think the role of small sat companies like Swarm will be in the space industry, or the world at large, over the next few years?

RM: This is what excites me about infrastructure as a service. We’ve seen the emergence of low-cost satellites, Swarm being the smallest of them. That seems like it’s here to stay, which is exciting. You combine that with low-cost launch and rideshare and ground station as a service. We’re now at the point where if you have an idea for a business you can build on top of this infrastructure and you may not need to invest in the space hardware at all. You might just invest in the payload, or the software signal that comes off that payload, or the analytics that process the imagery and measurements. The idea of using data generated from space to create an unlimited number of new businesses is exciting to me. And we’re getting there!

If you have an idea for a business, you can now build on top of existing infrastructure and you may not need to invest in the space hardware at all. The idea of using data generated from space to create an unlimited number of new businesses is exciting – and we’re getting there!

SS: My friend Rachel Olney is the founder and CEO of GeoSite, and they use spatial data for enterprise applications, like methane tracking or oil and gas monitoring. There are a lot of synergies between our companies because they can aggregate and serve data to non-technical users and we do sensing in situ and relay it – providing critical information into the system. But they have no satellite hardware, no launch, nothing. It’s just a software company that helps make the data usable by end customers.

RM: That’s a great example. It takes some very creative thought to get there. Everyone in the space industry wants to build their own satellite but we’re getting to the point where we don’t need to do that. You can just buy the bus and deliver the payload, like RocketLab’s Photon.

SS: We just launched with RocketLab! And all of our satellites turned on, so we’re very happy. Every time I watch a rocket go I still think it’s going to blow up – every single time. I’ve got to get over that!

RM: Yeah, we need to get past that. In this industry we’re not resilient enough yet. That’s what I love about Swarm. Of course there’s effort and money that goes into building the satellites, but the idea that having a large number of low-cost satellites with a quick hardware refresh rate because you’re taking advantage of new technology is pretty cool.

SS: How do you see Swarm as differentiated relative to other space or satellite companies?

RM: IoT is still a buzzword to a lot of consumers but it’s a really important market that many companies and industries are investing in. In the future, connected devices will be utilized to make life easier and that will require a secure and global network. And those are two things that Swarm is offering, at a very transparent price point, which many companies don’t have but is something customers are looking for.

In the future, connected devices will be utilized to make life easier and that will require a secure and global network. Those are two things that Swarm is offering at a very transparent price point, which many companies don’t have but is something customers are looking for.

SS: What are you most excited about with regard to Swarm?

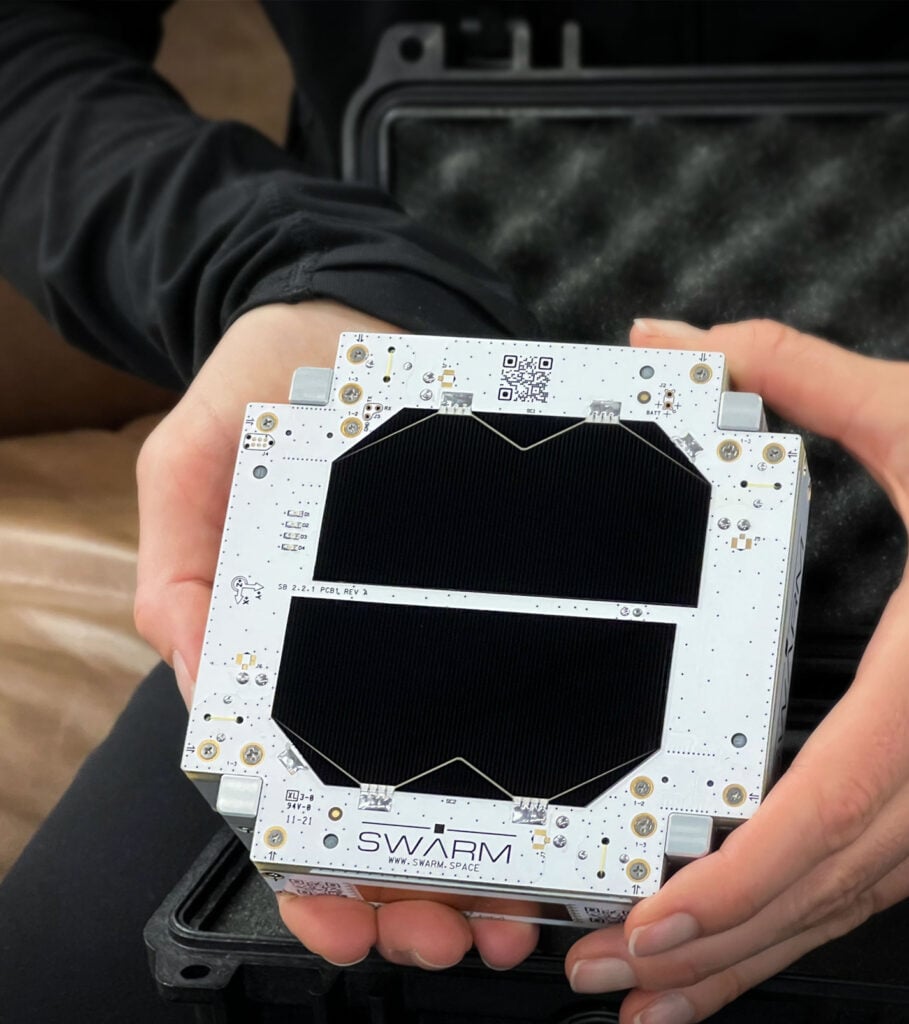

RM: I came to visit your lab last year and I was amazed at how small the satellites are. It’s really clever that, because they are 1/4U, you can flatpack them into a cubesat deployer. The cubesat form factor is so flexible. Most people are growing it to 6U and 12U and 24U and you’re taking it the other way. I don’t know if I’ve ever seen anyone else do that, and it keeps the cost down.

Also, the speed at which you’re deploying the system with such a small team is amazing. When I read your blog and see the progress you’ve made with a team that size, it’s kind of world-changing. It gives other founders inspiration that they can also do something global in nature.

When I see the progress Swarm has made with such a small team, it’s kind of world-changing. It gives other founders inspiration that they can also do something global in nature.

SS: Yeah, it’s super stressful and everyone is doing a million things but there is a sense of “Wow, we’re doing something crazy.” There is an enthusiasm about being the total underdog, which is cool.

RM: And that forces the incumbents to rethink things and compete.

SS: Yes, exactly. Turning to your own background, is there one habit or way of doing things that you think has made you successful throughout your career?

RM: Remembering people’s names! Some people think I just have a great memory but the truth is I work at it. When I meet somebody, I look them in the eye, I shake their hand – or I used to! – I take their business card and write notes on the back, and I put it into my contact list. Knowing people by name is a great habit for a leader because it’s an easy way to stand out from others.

Knowing people by name is a great habit for a leader because it’s an easy way to stand out from others.

SS: And finally, if you could moonlight for a week in another career, what would you do?

RM: I like this question! I’d like to combine my passion for space with travel and food and be a video blogger. I could visit companies and eat dinner with the founders and write about it. I’ve thought about it! I love what I’m doing right now but maybe down the road.

_____

This interview has been lightly edited for clarity and length.

Want more? Check out our inaugural Swarm Chat with Jonny Dyer, former Chief Engineer of Skybox Imaging.